The resources that OFFICINA 2000 industrial services has at its disposal are used in three different sectors (mechanical, plastic materials and railways). Among these, favorable synergies are activated, that enable to satisfy the multiple requests from the various clients.

MECHANICAL SECTOR:

Numerous machine tools are installed on the site of OFFICINA 2000 industrial services. These machines are able to offer a vast range of workmanship on different typologies of materials. The company workshop also includes a dedicated zone to carpentry and another specific one to carry out the various mounting and repairing of industrial apparatuses such as:

- Steam and gas turbines

- Centrifugal and alternative compressors, and others…

- All types of pumps

- Reducers and multipliers

- Fans

- Centrifugal separators

- Extruders and mixers for plastic materials

- Grinding Mills

- All types of valves

- Safety valves

The following activities are part of what we offer:

- Reconstruction of spare parts through reverse engineering

- Dynamic balancing on balancing machines as well as portable devices

- Predictive maintenance and diagnosis of the machine state through vibrational testing, thermography, SPM, etc…

- Installation and start-up of machinery

PLASTIC MATERIALS SECTOR:

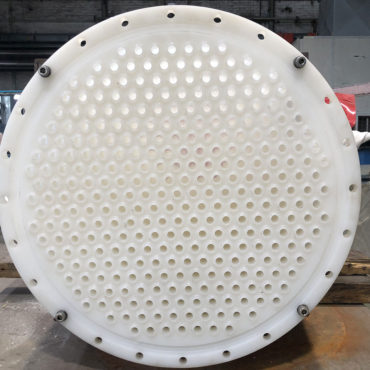

Our company boasts over 30 years experience and is specialized in the premanufacturing and mounting of piping and apparatuses with most of the plastic materials, both thermoplastic and thermohurdering, such as: PVC, PVCC, PE, PP, PVDF, HALAR, PRFV, etc…

This particular activity, with a dedicated area in the workshop, enables us to satisfy the chemical and pharmaceutical industries, besides offering all the applications dealing with non compatible fluids with metal materials. In this way, we established a virtuous collaboration between the plastic and mechanical plant engineering sector, thereby enabling OFFICINA 2000 industrial services to provide a varied and complete service, which is appreciated by many process industries. We are leaders in this type of activity in construction as well as plant maintenance.

RAILWAY SECTOR:

There are people within our Group from our OMP subsidiary that have been operating in the railcar maintenance and servicing sector in its components, for a number of years: safety units, frames and tanks, as well as maintenance and servicing interventions of Isotanks.

Our staff is certified according to the norms in force in the sector. There is a railway junction within our fully equipped premises, with specific machines (brake testing and suspension springs testing), thereby enabling us to receive freight wagons in our industrial sheds. Furthermore, we are equipped with mobile workshops, that permit us to carry out maintenance interventions outside our industrial plants (private junctions, stations, railroads, flush tracks, etc…).