The systems for the treatment of fumes in which our machines are applied consist in a dry technology, at the basis of which there is a chemical-physical reaction between the pollutant and various types of powder reagents (hydrated limestone, sodium bicarbonate, active carbons), able to neutralize it. It deals with a method that concerns a light installation, an easy managing of reagents involved and a controllable load of resulting products. Our great experience in this sphere derives from the multi-year collaboration with our partner Solvay, a market leader in bicarbonate, as well as being world leader in the production of sodium bicarbonate.

These skills acquired enable us to follow all the phases fulfilling the various systems of fumes treatment within our departments:

-

- Engineering

- Construction

- Assembling

- Commissioning/start-up

- After sales assistance

In function of the type of reagent involved we can provide four different technologies, being the result of our experience in the dry fumes abatement sector, and they make use of a series of accessories and instruments that are entirely designed, made and tested within our premises:

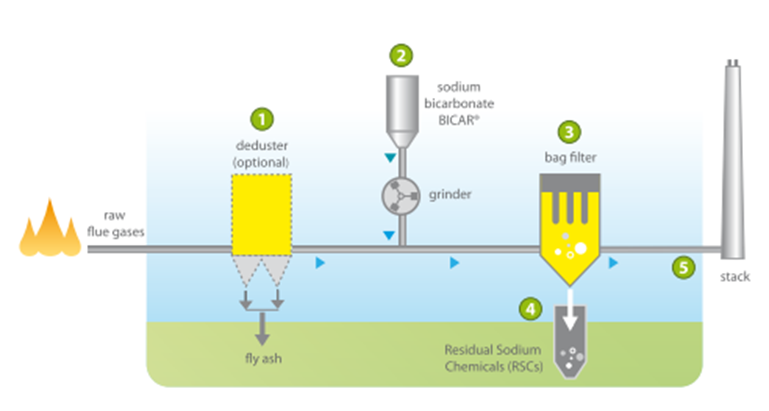

Fumes abatement through dosage, pneumatic transport and injection of sodium bicarbonate:

Through the SOLVAir® process, studied and patented by the Solvay company, that foresees a dry injection of sodium bicarbonate within the fumes deriving from combustion and industrial processes, it is possible to eliminate some pollutants that are harmful to the environment.

In fact, by putting the fumes with bicarbonate of sodium, being an alcaline powder, into contact at high temperature, the acids present in these fumes such as SOx, NOx, HCl, HF, etc…, neutralize themselves efficiently. Our mills, 2K and 2K Compact, guarantee the necessary granulometry in order to optimize the process mentioned.

Fumes abatement through dosage, pneumatic transport and injection of hydrated limestone:

Hydrated limestone (Ca(OH)2) is an alcaline powder. By injecting the reagent (in opportune conditions), emissions of acid substances are reduced (SOx, NOx, HCl e HF), those present in fumes deriving from combustion of industrial processes. Hydrated limestone has a very high fineness and hygroscopicity, for this reason our company has developed a specific line of products ensuring good reliability, covering a wide range of dosage volumes.

Fumes abatement through dosage, pneumatic transport and injection of active carbon:

Active carbon in powder form serves to reduce quantities of heavy metals (Hg, etc…), dioxins and furani that develop during industrial combustions. Our company is able to supply a vast range of products for dosage, transport and injection of this reagent, even with Atex 20/21 marking.

Fumes abatement through dosage, injection and pneumatic transport of “ready to use” bicarbonate:

Bicarbonate in a pre-ground version was introduced into the market several years ago with a Solvay patent. It deals with a type of bicarbonate that is ready to use, that we can dose, transport pneumatically and inject within the apparatuses for fumes abatement by means of our specific and effective apparatuses.